Electromechanical devices, called solenoid valves, control the flow of gases or liquids. They work on the straightforward but efficient premise that an electromagnetic coil produces a magnetic field when activated. A movable core (plunger) is drawn to this magnetic field within the valve body. The plunger’s movement then manages the fluid’s flow path.

Because of their exceptional adaptability, solenoid valves are used in various sectors and applications. These valves are essential to many systems and procedures, from contemporary cars’ complex functioning to medical equipment’s vital functions. They are crucial parts of numerous industries, such as industrial, automotive, HVAC, water treatment, and many more, because of their capacity to accurately control fluid flow.

To illustrate the versatility and sophistication of modern solenoid valves, consider the Burkert 6213. This compact and robust valve is popular in various applications due to its high flow capacity, rugged construction, a wide range of options, and easy integration.

The Burkert 6213 exemplifies how advanced solenoid valves can meet the diverse requirements of modern industries, offering high performance, reliability, and ease of use.

This article highlights the importance and influence of solenoid valves on contemporary technology and industries by examining their various applications in various fields.

Applications in Various Industries

Numerous industries have adopted solenoid valves, demonstrating their adaptability and essential function in contemporary technology.

They have a significant impact on the automotive industry. In fuel injection systems, solenoid valves are essential because they accurately regulate the amount of fuel delivered to the engine’s cylinders. Optimizing fuel-air mixes, guaranteeing effective combustion, and reducing hazardous emissions depend on this exact management.

Solenoid valves are also essential parts of contemporary automated transmissions. They coordinate clutch engagement, torque converter operation, and gear shifts by controlling the flow of hydraulic fluid. The driving experience is improved by this complex control, which guarantees seamless and effective gear changes.

The car industry prioritizes safety, and airbag deployment systems depend heavily on solenoid valves. These valves quickly release compressed gas in the case of an accident, inflating airbags to give passengers vital protection.

Furthermore, solenoid valves play a major role in emissions control systems. They are used in various systems, including selective catalytic reduction (SCR) systems and exhaust gas recirculation (EGR) valves to control exhaust gas flow accurately. The amount of dangerous emissions, such as nitrogen oxides, released into the atmosphere is reduced by this regulated flow.

The HVAC industry also heavily relies on solenoid valves. These valves regulate airflow within heating and cooling systems, controlling the opening and closing of dampers. This allows for precise control over airflow distribution, ensuring that different zones within a building maintain desired temperatures.

In addition, solenoid valves regulate water flow in boilers and chillers, optimizing heat transfer and maintaining efficient operating temperatures. Furthermore, they are vital in operating dampers within ventilation systems, ensuring proper airflow, and maintaining optimal indoor air quality.

In the manufacturing sector, solenoid valves are indispensable components in various applications. They are integral to pneumatic and hydraulic systems in various machinery, such as presses, robots, and conveyors. By controlling the flow of compressed air or hydraulic fluid, these valves enable precise and rapid movements of mechanical components, enhancing the efficiency and productivity of manufacturing processes.

In chemical processing plants, solenoid valves are critical in controlling the flow of various chemicals and fluids. This precise control ensures accurate dosing, mixing, and reaction processes, optimizing chemical reactions and maintaining product quality.

Automated assembly lines heavily rely on solenoid valves. These valves control the movement of components, activate tools, and regulate the flow of materials, enabling the efficient and precise coordination of various stages within the assembly process.

The water treatment industry also benefits significantly from the versatility of solenoid valves. These valves control water flow throughout various treatment processes, such as filtration, purification, and disinfection.

Furthermore, they play a crucial role in precisely regulating the dosage of chemicals added to water during treatment, such as chlorine or fluoride. This precise control ensures the effectiveness of treatment processes while minimizing the risk of overdosing.

In irrigation systems, solenoid valves control water flow to different zones, optimizing water usage and preventing overwatering. This contributes to water conservation and minimizes environmental impact.

The medical field relies heavily on solenoid valves for critical applications. In dialysis machines, these valves precisely control blood flow and dialysate, ensuring the efficient removal of waste products from the blood of patients with kidney failure.

In anesthesia machines, solenoid valves are crucial in controlling the flow of anesthetic gases and oxygen, ensuring these vital substances’ safe and precise delivery during surgical procedures.

Moreover, solenoid valves regulate the flow of various medical gases, such as oxygen and nitrous oxide, in different medical devices and equipment, ensuring the proper functioning of these critical systems.

Solenoid valves are crucial to the food and beverage sector because they regulate the flow of gases and liquids in various processing applications, including pasteurization, filling, and bottling.

Additionally, they are essential to beverage dispensing systems since they guarantee precise and reliable beverage distribution.

Last but not least, solenoid valves regulate the flow of flavors, syrups, and additives during food preparation, guaranteeing product quality and avoiding contamination.

Benefits of Using Solenoid Valves

Solenoid valves are widely used in many industries because of their enticing benefits. Perhaps its most remarkable quality is its adaptability. These valves handle numerous fluids, including water, oils, caustic chemicals, and aggressive gasses. Additionally, they can function at a variety of pressures and adjust to the needs of various applications.

Reliability is another key strength. Constructed from durable materials, solenoid valves are designed for long-term operation with minimal maintenance. Their robust design ensures consistent performance even in demanding environments, minimizing downtime and operational disruptions.

Furthermore, solenoid valves excel in terms of efficiency. Their precise control over fluid flow minimizes waste and optimizes resource utilization. This enhances operational efficiency and contributes to environmental sustainability by reducing energy consumption and minimizing environmental impact.

Another important advantage is the simplicity of integration with automated systems. They are perfect for integrating complex control systems due to their small size and easily accessible control interfaces. This makes automation easier, streamlines procedures, and boosts output all around.

Lastly, it is impossible to ignore how economical solenoid valves are. Their long-term advantages, like lower maintenance, more output, and increased efficiency, frequently outweigh the original outlay, even though it may vary. Solenoid valves may greatly reduce costs and increase profitability by reducing downtime, maximizing resource use, and improving overall operational performance.

Optional Sections

Selecting the appropriate solenoid valve for a specific application requires careful consideration of several key factors. Fluid type plays a crucial role, as compatibility with the valve materials is essential to prevent corrosion and ensure proper operation. Pressure requirements must also be carefully evaluated to select a valve capable of withstanding the intended operating pressures without leakage or damage. Flow rate demands must be met to ensure the valve can deliver the required fluid volume within the desired timeframe.

Furthermore, the electrical characteristics of the valve, such as voltage and current requirements, must be carefully matched to the available power supply. Operating temperature ranges must also be considered to ensure the valve can function reliably within the expected environmental conditions. Finally, size and mounting options should be considered to ensure compatibility with the available installation space and system requirements.

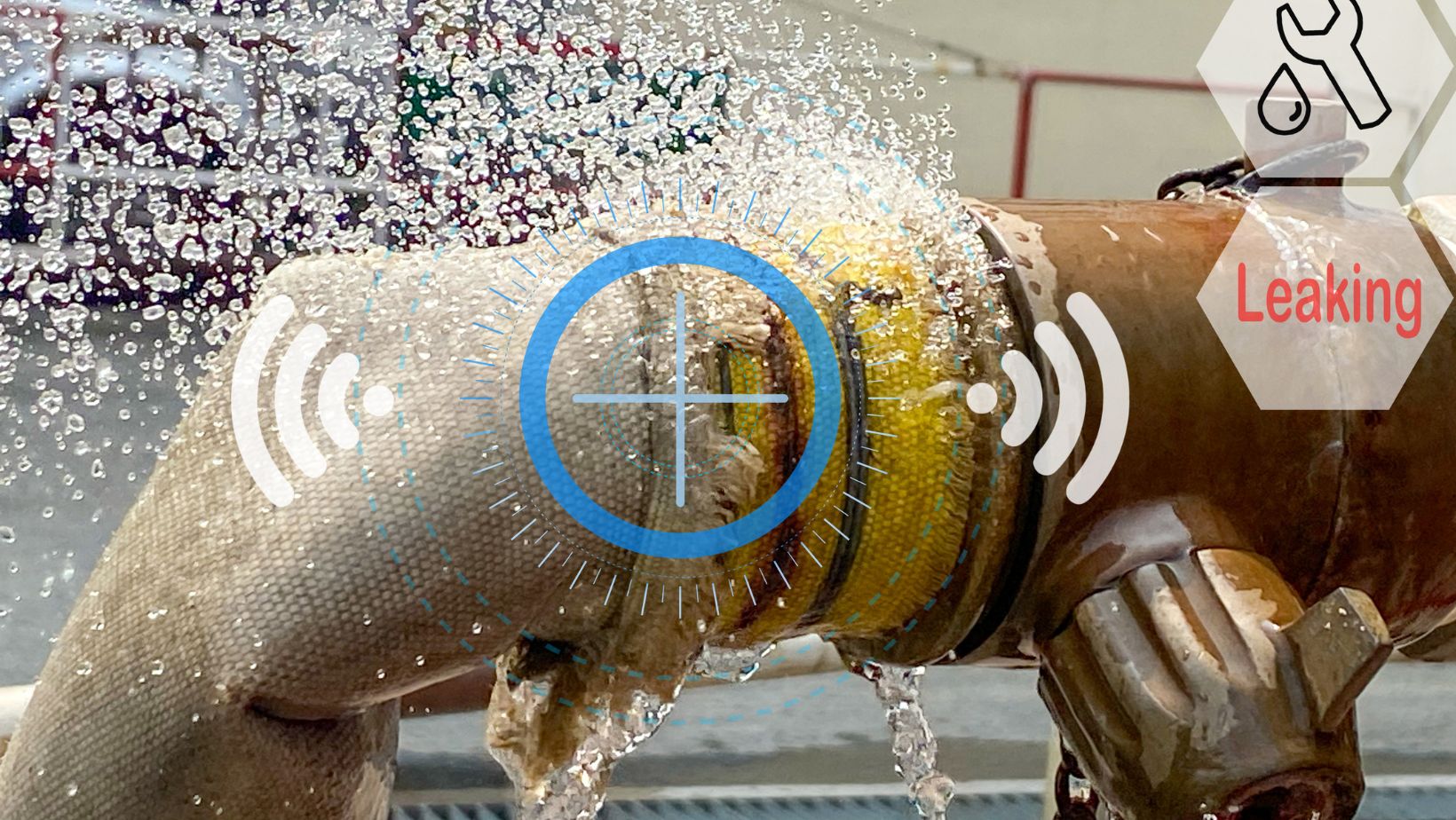

Proper maintenance is crucial for ensuring solenoid valves’ long-term reliability and performance. Regular inspections can help identify potential issues early on, such as leaks, worn seals, or signs of corrosion. Routine cleaning and lubrication, as the manufacturer recommends, can help maintain optimal performance and extend the valve’s lifespan.

Troubleshooting involves systematically identifying and resolving issues that may arise during operation. Common problems include intermittent operation, leakage, or complete failure to function. Troubleshooting may involve checking electrical connections, inspecting for blockages or debris, and testing the solenoid coil for proper operation. Sometimes, it may be necessary to consult the manufacturer’s technical documentation or seek assistance from a qualified technician.

By carefully considering these factors and implementing proper maintenance and troubleshooting procedures, users can ensure their solenoid valves’ optimal performance and longevity, maximizing their benefits in a wide range of applications.

From manufacturing and automotive to water treatment and medicine, solenoid valves have demonstrated their adaptability and necessity in various industries. They are essential for regulating fluid flow, which permits accurate and effective functioning in multiple applications.

There are many advantages to using solenoid valves, including increased cost-effectiveness, efficiency, dependability, and simplicity of integration. Their capacity to precisely regulate fluid flow reduces waste, maximizes the use of available resources, and enhances system performance. Additionally, their sturdy construction and small size make it simple to incorporate them into automated systems, streamlining processes and boosting output.

Solenoid valve technology has a bright future ahead of it. More robust and corrosion-resistant valves are being developed due to advances in materials science, and continuous shrinking initiatives are making it possible to create even smaller and more compact devices. Furthermore, solenoid valve operation is about to revolutionize thanks to the integration of smart technologies like sensors and artificial intelligence, enabling improved control capabilities, real-time performance monitoring, and predictive maintenance. Solenoid valves will continue to lead fluid control solutions as technology advances, becoming increasingly important in determining the direction of numerous industries.