In the fast-paced world of industrial equipment, reliability is crucial for maintaining efficiency and reducing downtime. Pogo pins have emerged as a popular choice for electrical connections due to their ease of use and compact design. This article explores the long-term reliability of pogo pins in industrial settings, examining factors like durability, performance under stress, and maintenance needs to help businesses make informed decisions about their use.

Overview of Pogo Pins

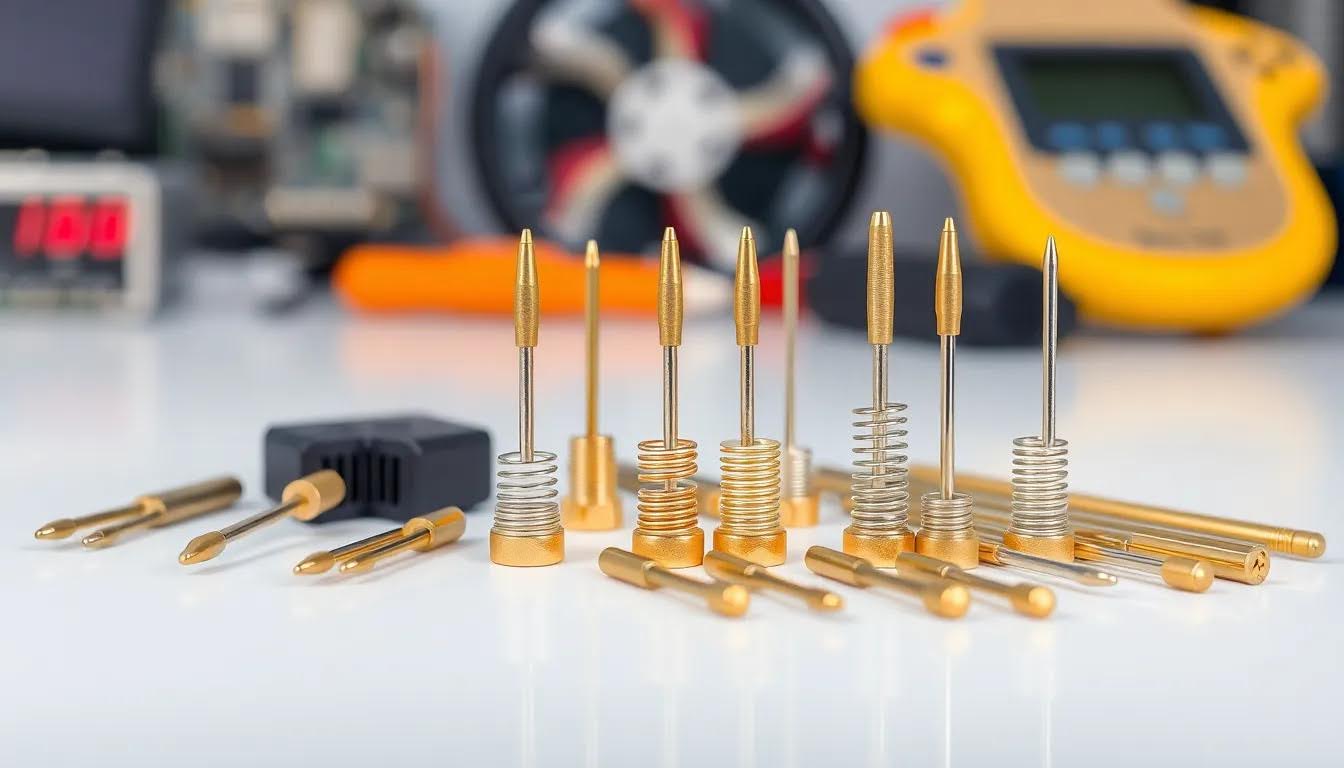

Pogo pins, also known as spring-loaded connectors, provide reliable electrical connections in various applications. These components feature a spring mechanism that allows for movement and contact with corresponding pads or sockets. Companies like Promax utilize these connectors in their designs due to their compact size, which fits easily into tight spaces within industrial equipment. Pogo pins excel in durability. Constructed from high-quality materials like stainless steel or gold plating, they resist wear over time. Their resistance to corrosion and oxidation enhances longevity, making them suitable for harsh environments. Performance under stress remains critical. Pogo pins maintain connectivity across vibrations and thermal fluctuations experienced in industrial settings. This stability ensures consistent performance throughout the lifecycle of the equipment. Maintenance requirements are minimal compared to other connection types. Regular inspections can identify any wear on pogo pins, ensuring they function optimally without extensive downtime. Overall, pogo pins serve as an effective solution for long-term use in industrial equipment due to their reliability, durability, and low maintenance needs.

Understanding Pogo Pin Technology

Pogo pins, or spring-loaded connectors, offer reliable electrical connections essential in industrial settings. Their design and functionality significantly improve their utility in various applications.

Design Features

Pogo pins feature a compact structure consisting of a conductive pin and a spring mechanism. The spring allows the pin to compress and extend, ensuring consistent contact with corresponding pads or sockets.

Functionality in Industrial Applications

Pogo pins excel in maintaining connectivity under challenging conditions common in industrial environments. They perform well under vibrations, thermal fluctuations, and mechanical stress. This capability ensures stable electrical connections across various equipment types during operation. Minimal maintenance requirements further contribute to their effectiveness; regular inspections suffice to identify wear without requiring extensive downtimes for repairs or replacements. Overall, pogo pins deliver reliable performance crucial for long-term use in industrial equipment settings.

Reliability Factors of Pogo Pins

Pogo pins exhibit several key factors that contribute to their reliability in industrial applications.

Material Considerations

Materials significantly influence the performance and longevity of pogo pins. High-quality stainless steel is a common choice due to its strength and resistance to corrosion. Gold plating enhances conductivity while preventing oxidation, which is essential for maintaining electrical connections over time. The choice of materials directly impacts wear resistance, ensuring consistent functionality even in demanding conditions.

Environmental Influences

Environmental factors affect pogo pin reliability during long-term use. Exposure to moisture, dust, temperature fluctuations, and chemical agents can impact performance. Pogo pins designed for industrial settings often feature protective coatings that mitigate environmental damage. Their spring-loaded design allows them to maintain reliable contact despite vibrations or shocks from machinery operation, further enhancing their durability in harsh environments.

Comparative Analysis

Pogo pins demonstrate reliability compared to alternative connectors in industrial settings. This section compares pogo pins with other connection types and presents case studies that illustrate their long-term effectiveness.

Pogo Pins vs. Alternative Connectors

Pogo pins outperform many alternative connectors, such as soldered connections, wire-to-board connectors, and terminal blocks.

-

- Connection Stability: Pogo pins maintain stable connections under vibrations and thermal shifts due to their spring-loaded design.

-

- Ease of Integration: Pogo pins require minimal space, making them suitable for compact equipment where traditional connectors may not fit.

-

- Durability: Pogo pins resist wear from repeated use better than soldered connections or terminal blocks, which can degrade over time.

-

- Maintenance Needs: Pogo pins demand less maintenance than mechanical connectors like terminal blocks, which often require more frequent inspections.

These advantages make pogo pins a preferred choice in demanding environments.

Case Studies of Long-Term Use

Several companies have successfully implemented pogo pins in their industrial applications.

-

- Automotive Industry: A leading automotive manufacturer adopted pogo pin technology for its assembly lines. After five years of continuous use, the company reported no significant failures, demonstrating the durability of pogo pins amid high vibration levels.

-

- Consumer Electronics: A consumer electronics firm utilized pogo pins for charging stations in mobile devices. Over three years, they observed consistent performance without any loss of connectivity or signal degradation

-

- Medical Devices: In medical device manufacturing, a company incorporated pogo pins into diagnostic equipment used in hospitals. The equipment operated reliably for over four years without failure due to environmental factors like moisture and temperature changes.

These examples underscore the effectiveness and longevity of pogo pin connections across various sectors.

Industry Insights

Pogo pins are increasingly recognized for their reliability in industrial applications. Their performance in demanding environments makes them a critical component of modern equipment.

Expert Opinions

Experts emphasize the importance of material selection in pogo pin durability. High-quality stainless steel and gold plating provide superior resistance to corrosion and wear. Engineers note that these materials improve electrical connectivity, which is vital for long-term use. Additionally, experts recommend regular inspections to identify any signs of degradation early, ensuring optimal functionality throughout the equipment’s lifecycle.

User Experiences

Users across multiple industries report satisfaction with pogo pins’ performance. In automotive manufacturing, technicians highlight their effectiveness under conditions involving high vibrations and thermal fluctuations. Feedback from consumer electronics companies indicates minimal failures over extended periods, reinforcing confidence in pogo pins as a reliable choice for electrical connections. Users in medical device production also cite low maintenance requirements as a significant advantage, allowing for streamlined operations without frequent interruptions.

Conclusion

Pogo pins prove to be a dependable choice for long-term use in industrial equipment. Their robust construction and innovative design ensure reliable electrical connections even in challenging environments. With minimal maintenance needs and high resistance to wear and corrosion, these connectors stand out as a durable solution.