Fabless semiconductor company Astera Labs has recently raised $50M to develop their AI hardware designs. This is a great achievement for the company, yet there are still many challenges in developing these designs.

AI hardware companies face various issues attributed to their limited resources, the lack of understanding of new technologies, and the currently available AI-designs.

In this article, we’ll look at these challenges and how AI companies work around them.

Fabless semiconductor company Astera Labs raises $50M for AI hardware designs

Fabless semiconductor company Astera Labs is a leading AI-inspired hardware design provider that fuels the modern computing industry. Their mission is to accelerate the adoption of AI and create innovative solutions for next-generation computing systems. By leveraging the most advanced simulation algorithms, Astera Labs ensures their clients have the highest quality AI solutions for their business objectives. The company has recently announced a Series C funding round worth $50 million, which will help support the various projects it is currently undertaking.

Astera Labs provides hardware design and software development services for AI applications, utilising its robust portfolio of products and technologies. In addition, global OEMs can access cost-efficient yet powerful integrated optimization services through its mediums such as AsteriOS, an advanced system optimised for running AI/ML workloads. With this funding round led by ICONIQ capital,astalos plans to expand its offerings in data centres, IoT edge devices and automotive chipsets.

Aiming to bring automated real-time hardware design to the mass market while eliminating manual hardware engineering effort on state-of-the art chipsets such as Xilinx Ultrascale+, Astera Labs offers unique competitive advantage over others competing in the industry. With several greenfield projects already being undertaken with customers across SEA and US markets, skilled teams like Astera are helping bridge the gap between current challenges in AI/ML development by allowing companies to consume ready-to-run components off shelf faster than ever before – driving operational efficiency at low cost points surpassing those achievable in manual system engineering cycles for chip programming.

Challenges Faced by AI Hardware Companies

AI hardware companies face several challenges as they create products that provide the best performance for their customers. These challenges include the need for strong R&D capabilities, large startup costs, and the complexity of scaling up production.

Let’s take a look at some of these challenges in more detail.

High cost of development

The rapid advancement of artificial intelligence has created a major new opportunity for those in the hardware space. A fabless semiconductor company like Astera Labs can provide AI hardware designs tailored to various customer needs. However, there are several challenges that these companies face when developing their designs, notably the high cost associated with the development.

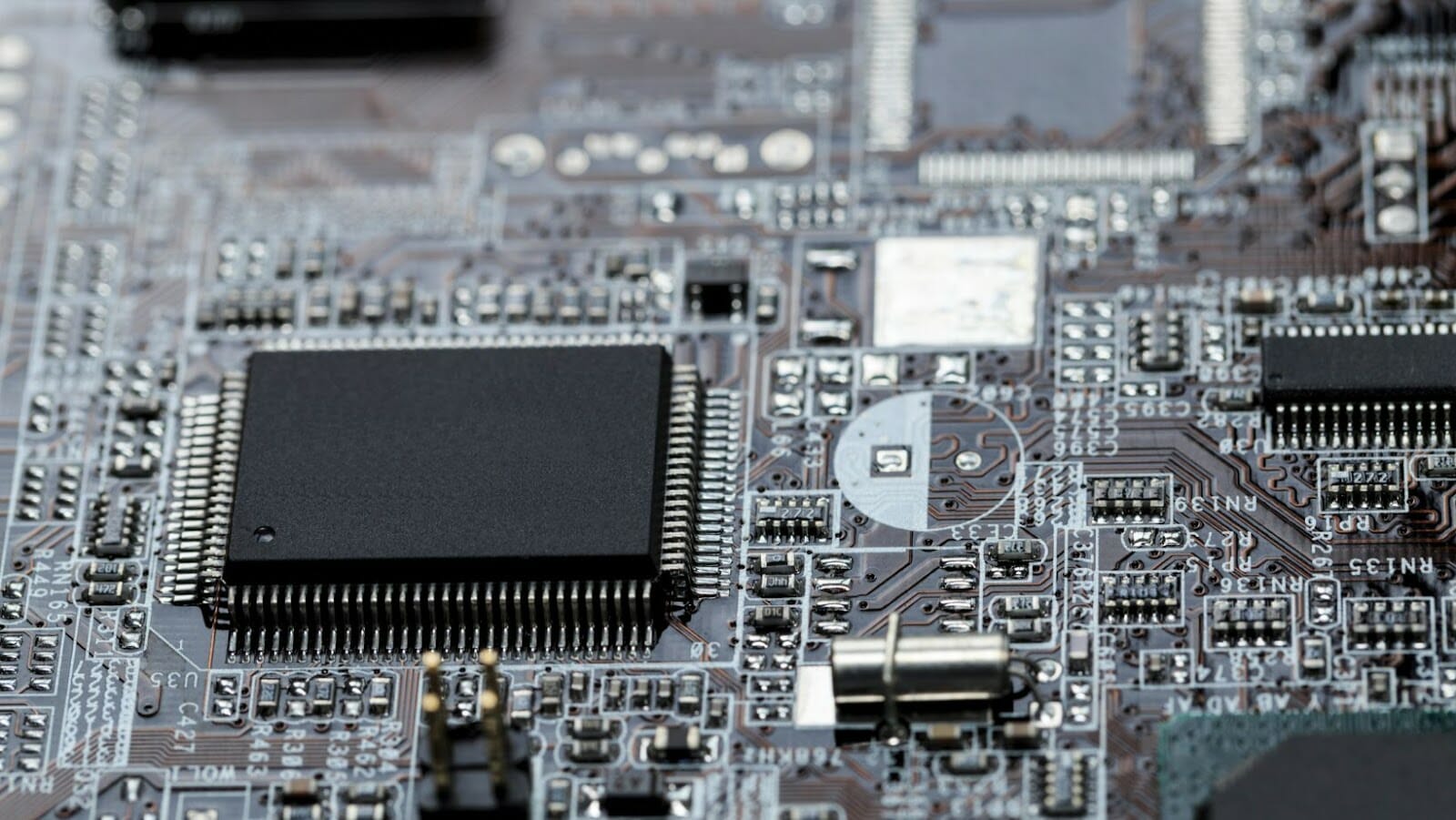

The development process for any chip design project is complex and time consuming, requiring significant financial investment before any ROI can be seen. From conception and selection of an appropriate manufacturing process, to characterization, qualification and testing; each stage incurs cost at an up-front engineering cost and recurring fabrication costs. When designing for AI applications specifically, there is also added complexity due to the sheer amount of data handling required which requires vast amounts of memory and unique compute architectures that facilitate rapid processing and decisions. This sophisticated nature of the required hardware can significantly increase the project’s costs and risks associated with development compared to developing traditional electronics products on a normal timeline.

Furthermore, today’s tight competition in AI hardware often means tight lead times from concept through to materialisation – requiring more resources and tight control over project budgets for customers’ products to come onto the market quickly so as not to miss out on market share. Considering all this – it is no surprise that fabless semiconductor companies need adequate funds to develop competitive chip designs in this AI era!

Low market demand

One of the biggest challenges AI hardware companies face is low market demand. AI hardware is complicated and expensive to develop and produce, which can be a major hurdle for many hardware companies. Additionally, the AI industry is in its early stages and AI integration is not yet widely accepted. This can make it difficult for companies to justify investing high capital in developing new technologies.

Furthermore, low demand has made it difficult for many AI hardware companies to reach a larger customer base. For example, fabless semiconductor company Astera Labs recently raised around $50M in funding for their AI hardware designs but still faces challenges when finding buyers of those designs. Other issues include limited customer understanding that could impede product uptake and decrease ROI from research and development efforts.

To tackle these problems, some tech giants are developing innovative strategies such as partnering with other chip makers for distribution networks or offering proprietary products/systems that feature their AI technology at competitive pricing points to attract customers. However, startups trying to enter this field need proper guidance on developing feasible products that meet customer demands while still being profitable enough to sustain long-term operations in this highly competitive industry.

Lack of technical expertise

One of the biggest challenges AI hardware companies face is a lack of technical expertise. Developing AI hardware is a highly specialised endeavour requiring advanced knowledge in machine learning, computer architecture, and semiconductor design. Because this skill set is not widely available, hardware companies must invest significant resources into training and recruiting personnel with the right expertise.

Hard-to-find components can cause supply chain delays, resulting in significant cost overruns.

Traditionally, designing AI hardware has been expensive and time-consuming since companies needed to design their chips from scratch. To reduce these costs and speed up the process, many companies are now opting for what’s known as “fabless” semiconductor design — this means that they rely on third-party suppliers such as Astera Labs to create their custom chips for them. Fabless semiconductor design allows for faster time to market and lower costs; however, it can still be difficult for smaller AI hardware companies to find suitable suppliers or raise enough capital investments for custom chip designs.

Difficulty in finding skilled labour

Finding skilled labour is one of the biggest challenges facing AI hardware companies. This is often complicated because the industry requires relatively few employees, while requiring extensive technical knowledge and training before they can be considered effective. This has led to an imbalance between the number of qualified employees capable of working in AI hardware and the demand for them. As a result, there are more positions than qualified engineers with knowledge in software, networking and other specialised areas.

To address this issue, companies like Fabless semiconductor company Astera Labs have had to seek out alternative sources of labour – either through training existing personnel or hiring external experts. Additionally, efforts have been made to nurture resources through internships and scholarships which help encourage young engineers towards a career in AI hardware development. Finally, companies such as Astera Labs have also sought venture capital funding to expand their employee pool and increase their technological capabilities for hardware production and design.

Difficulty in scaling up production

One of the primary challenges AI hardware companies face is scaling up the production process from prototype to mass production. This highly complicated process requires a deep understanding of design, manufacturing, testing and quality assurance. For an AI product to be commercially viable, it must undergo rigorous tests and have flawless production quality. However, even if the initial design is of excellent quality, scaling up the production may lead to faults due to time lags or misunderstandings between different processes.

Moreover, as products become more sophisticated and use more intricate processes like deep learning algorithms on chips with specialised architectures, this becomes an even tougher challenge. Companies must ensure that their chips function optimally and reliably in commercial settings while providing economic viability. The costs associated with complex assembly processes further compound this challenge as a chip must only include the components essential for the task while maintaining a competitive cost structure.

The prevalence of fabless semiconductor companies demonstrates the difficulty in managing design-related costs and product complexification simultaneously – thus paving the way for firms such as Astera Labs who reportedly raised $50M for AI hardware designs –seeking to bridge this gap through extensive investments into research & development projects. It is hoped that these investments will enable innovation in this field while mitigating associated risks to pave the way for industry wide disruption associated with cutting edge technological advancements within artificial intelligence hardware segments.

Intense competition

The AI hardware market is characterised by intense competition. Numerous global companies (big and small) are vying for supremacy in this space, and technological advances can be quickly replicated. This leaves fabless semiconductor companies like Astera Labs in an incredibly difficult position: they must develop efficient, scalable products that outperform the competition while remaining cost-effective.

To succeed, fabless semiconductor companies must have a clear vision of their product offering based on extensive research and a determined focus on customer needs. As an AI hardware company, Astera Labs had been developing a set of chips designed to solve common computer vision challenges with better clarity than existing solutions. To fund the subsequent development of these chips, the company recently secured $50 million in venture capital funding from investors across multiple industry verticals — rivalling the backed investments of larger tech incumbents like Intel or Qualcomm.

AI hardware companies face challenges such as obtaining and retaining top engineering talent, navigating complex technology regulations, staying abreast of the latest innovations in AI hardware technologies and convincing customers to invest in their solutions over others. For Astera Labs to successfully bring its new chip designs to market and stay competitive within an increasingly crowded AI hardware industry landscape, it must overcome all these challenges.

Impact of the Astera Labs Funding

The recent $50 million investment in Astera Labs, a fabless semiconductor company specialising in AI hardware designs, has brought to light the financial challenges that AI hardware companies face.

The injection of capital points to the rising demand for specialised AI hardware and the importance of investment for developing advanced AI technologies.

This article will discuss the key implications of the Astera Labs funding.

Increased investment in AI hardware designs

Astera Labs recently announced that it secured a funding of $50 million, led by Coatue Management, to fuel the development of customised AI and high-performance computing hardware. This capital infusion is expected to create major market opportunities for the fabless semiconductor company.

The increased investment in AI hardware designs will offer a variety of advantages to the industry, including cost savings, rapid development cycle and shorter time-to-market. It will also help accelerate and bring advanced technologies such as edge computing, surveillance systems, connected vehicle platforms and deep learning accelerators to market. The additional resources also allow for significant R&D efforts to meet customer needs faster with innovative hardware engineering and software integration solutions.

However, amidst this change in the market dynamics due to increased investment in AI hardware designs, there are certain challenges related to long lead times on major milestones due to larger team size, managing a distributed supply chain operation, and quickly ramping up production when customer orders come in floods. Addressing these issues requires dedicated efforts of operations management teams who have intricate knowledge about each facet of the manufacturing process.

It remains to be seen whether Astera Labs can successfully overcome these hurdles or not. Still, one thing is certain that this much needed infusion of capital will go a long way for emerging players in the field who are currently trying their best to hone their products with emergent technologies like AI.

Improved access to resources

Thanks to the $50M series B funding round led by Matrix Partners, Astera Labs is proficiently positioned with access to the resources and backing needed to develop their AI chip designs. This influx of capital has enabled them to pursue advanced manufacturing processes, invest more heavily in engineering and R&D capabilities, hire additional talent, and support customer demands.

The investment will also enable Astera Labs to ramp up production and distribution of their products while providing new opportunities for faster speeds, lower costs, and greater accuracy. Additionally, this round of funding will allow the Fabless semiconductor company to expand its team focused on software development and algorithms needed for future advancement in AI hardware designs.

Advanced manufacturing processes allow AI chip companies like Astera Labs to reduce risk and break into new markets with their innovative products. By leveraging these same technologies and processes along with investments from Matrix Partners, Astera Labs can build on their success as a Fabless semiconductor company by taking advantage of improved resources designed for developing reliable AI hardware designs.

Enhanced technical capabilities

With the influx of $50M in funding raised by fabless semiconductor company Astera Labs, AI hardware designs can now benefit from enhanced technical capabilities. This new milestone unlocks the potential of AI hardware designs to interact with advanced technologies, creating technology-driven solutions for many industries. With this capital injection, Astera Labs can now invest more resources into research and development for next-generation AI hardware designs. This will take advantage of energy efficiency and deliver faster processing times. As a result, AI hardware designers can leverage these new capabilities to design faster and smaller electronic devices requiring less energy.

However, with enhanced technical capabilities come various challenges that must be overcome before any advancements can be fully taken advantage of. Increased power consumption is one such challenge as powering more complex algorithms requires more energy consumption leading to increased costs for the user-level operations. In addition, new workloads need to be integrated into the existing framework and adapted accordingly which often require additional certification processes or even changes in legislatures; especially in industries such as health or automobile technology where safety factors must always remain a priority despite the introduction of newer technologies and platforms. Finally, data-set complexity is also important since textual analysis and natural language processing projects typically require larger datasets than traditional algorithms as they are responsible for assessing environmental factors that are not always linear; making them inherently harder to define or model mathematically.

tags = Astera Labs, Fabless semiconductor company, raises $50M, AI hardware designs, Fidelity, astera labs series fidelity 950m 85mwiggersventurebeat, Sanjay Gajendra, founded in 2017 by Jitendra Mohan, target chipset challenges in datacenters